The terms propeller shaft (prop shaft) and drive shaft can sound similar in vehicle mechanics terminology, but both perform different functions in the power transfer process to the wheels, depending on the type of vehicle and the design.

Both shafts transfer power to the wheels, but serve different purposes, functions, applications, and maintenance requirements.

In this article, we will help you understand the differences between a prop shaft and a drive shaft, how they function, their applications, and maintenance.

What is Propeller Shaft?

The propeller shaft is the component that transmits mechanical power through torque and rotation as well. These shafts are also called driveshafts, driving shafts, tail shafts, or Cardan shafts.

The purpose of the driveshaft is to transmit torque between components that cannot be connected directly to each other because of distance or because relative motion must be permitted between them.

As the driveshaft carries torque, it experiences torsion or shear stress, so they should be strong enough to carry the stress but not so heavy that it increases the overall inertia of the driveshaft.

Driveshafts are utilized differently in different vehicles, with different arrangements for front wheel drive (FWD), four wheel drivetrain (4WD), and front engine/rear wheel drive (FR).

Driveshafts are also utilized in motorcycles, locomotives, marine ships, etc.

What is a Drive Shaft?

A drive shaft transmits power from the transmission or transfer case to the wheels. It is similar to the prop shaft, but is used in more vehicles. A drive shaft turns the engine’s rotational energy into the torque that will turn the tires and move the vehicle forward or backward.

There are often times when the words prop shaft and drive shaft are interchangeable, but that is not always true. All vehicles with a transmission will have drive shafts. Power must go from the transmission to the wheels, and a prop shaft is a type of drive shaft. However, it is incorrect to call a front drive axle shaft or front drive shaft a prop drive shaft.

Different drive shafts are used for different vehicle applications:

- Solid drive shaft – Used in most rear-wheel drive vehicles, this single-piece drive shaft connects or transmits power from the transmission to the rear differential.

- Two-piece drive shaft – In longer platforms like trucks and buses, it may not be practical or cost efficient to have a single drive shaft when the two components (transmission and rear differential) are separated by a long distance because the drive shaft would be very long. Therefore, a two-piece drive shaft will be used.

- Front drive shaft – Found in four-wheel drive vehicles, the front drive shaft is a much smaller drive shaft that transfers power to the front differential to allow the front tires to be powered in four-wheel drive.

- CV axle shaft – CV axles are typically used for wheels with independent suspension. More specifically, they are used in front-wheel drive and 4-wheel drive (AWD) models. CV axles go directly from the transmission or differential to the steering knuckle for power distribution and transfer.

Prop Shaft vs. Drive Shaft

Prop shafts and drive shafts are similar as they transfer power to the vehicle’s wheels, but there are key differences between both terms and their function.

Prop shafts can only be found in rear-wheel-drive and four-wheel-drive vehicles while drive shafts can apply to any shaft that transmits power to the wheels.

Prop shafts connect rear differentials to the engine to allow rotation to transfer power to the drive wheels. Drive shafts in front-wheel vehicles can be any shaft transmitting power to the wheels.

Prop shafts connect the driveshaft to the vehicle and, as a result, prop shafts tend to be long. Drive shafts, being front-wheel drives, tend to be smaller in overall size than prop shafts.

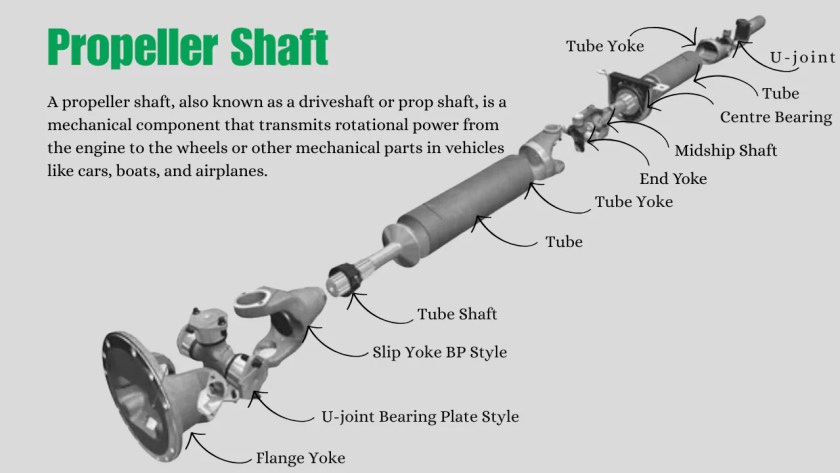

Parts of Propeller Shaft

The main parts of the propeller shaft:

- U-joint

- Tube

- Centre bearing

- Midship shaft

- End yoke

- Slip yoke and Tube yoke

- Flanges

#1. U-joint.

A U-joint is a mechanical joint used to connect rotating shafts. As of today, we mostly see the driveshaft and universal joints in rear-wheel and four-wheel drive.

#2. Tube.

A tube is a part of a drive shaft, It’s often used in front engine and rear drive automobiles. The purpose of using a tube is to keep the rear end in-place during acceleration and braking.

#3. Center Bearing.

The center bearing is going to connect the two sections of the drive shaft. These bearings are ment to keep both driveshaft components solid to reduce harmonic resonations when the vehicle is accelerating.

#4. Mid Ship Shaft.

Midship shafts are the basic component of a coupling shaft and are part of a drive shaft that is going to be attached to the frame on a center bearing.

#5. End Yoke.

An end yoke is used fore accurately and durable purposes. A benefit of using an end yoke is to help reduce noise and vibration to help your driveline run easily.

#6. Slip Yoke and Tube Yoke.

A slip yoke is going to be attached to the driveshaft itself using a universal joint, the slip yoke is fitted to transfer power by sliding in and out of the transfer case, the tube yoke is going to be necessary so that the U joints can rotate well with the drive shaft.

#7. Flanges.

Flanges are going to be used for automotive purposes to connect the driveshaft transmission, transfer case, and differential. Flanges are also used to connect driveshafts to power take-offs, hydraulic pumps, and various accessories.

Functions of the Propeller Shaft

In vehicles, when the engine is in the front position, the front wheels of the vehicle are being driven; but some vehicles have the engine at the rear, and the rear wheels are being driven to do this a small propeller shaft is used to drive each wheel.

The engine and transmission units are attached to the frame and supported by flexible mountings or bearings. The rear axle, differential and wheels are also attached to the frame, but supported by a suspension spring.

If we take a closer look at the setup above, the transmission output shaft and the input shaft in the rear axle housing are in different planes; therefore, the propeller shaft that connects these two shafts must remain at an angle.

Also, when the rear wheels encounter unevenness in the road the rear axle moves in the up and down direction, causing the suspension spring to compress and expand. The angle between the transmission output shaft and the propeller shaft will also change.

The propeller shaft length is also changing based on the propeller shaft and rear axle rotating on arcs, as well as movement at the points of rotation for each axis.

Propeller Shaft Material

Propeller shaft is made of hardened steel, in tubular form. The center bearing is located between two propeller shafts. Similarly, the propeller shafts is also made of alloy steel and there is a spring steel option available as well.

Types of Propeller Shafts

Types of propeller shaft included below:

- Single piece type

- Two or three-piece type

#1. Single Piece type.

This type of propeller shaft is used in vehicles that have a small distance to travel between the engine and the axle, such as in front-wheel drive vehicles, or 4×4 vehicles.

Single piece propeller shafts may use friction welding to increase strength, quality and durability of the shaft.

#2. Two or Three Piece type.

Two or three-piece propeller shafts are used in vehicles with a longer distance between the engine and the axle and four-wheel drive vehicles.

By splitting the propeller shaft into two or three pieces it reduces the large number of revolutions can be accomplished with a large diameter shaft.

Conditions of Propeller Shaft

To serve efficient purposes, the propeller shaft needs to be:

- High torsional Strength

- Toughened and hardened

- Efficiently combined

- Dynamically balanced

- Low thrust load

#1. High Torsional Strength.

They must be made of a rod or hollow rod to obtain high torsional strength in the working.

#2. Toughened and Hardened.

Hard and rigid materials are normally needed to make these, so they are made of high-quality steel and induction hardened.

#3. Efficiently Combined.

They have to be tightly combined when being used, therefore they are typically welded together by a submerged carbon dioxide welding process.

#4. Dynamically Balanced.

Since the rotation factor might be crucial at high speeds, the propeller shaft is tested on an electronic balancing machine.

#5. Low Thrust Load.

Since the resonance is bad for the life of the shaft. To avoid this phenomenon, they transmit excess dynamic force to the end support of the shaft.

Conclusion

The propeller shaft is important to the drive axle. It supplies rotational torque from the gearbox and engine to the drive axle while allowing relative motion between the gearbox and the drive axle.