Engine valves are critical mechanical components used in internal combustion engines, responsible for controlling the flow of fluids or gases into and out of the combustion chambers (cylinders) during engine operation.

Functionally, they operate like other types of valves by blocking or allowing flow but are uniquely designed to interface with other engine components, such as rocker arms, camshafts, and lifters, to ensure precise timing and sequencing of opening and closing actions.

The term engine valve can also refer to a type of check valve used in air injection systems for vehicle emission control and exhaust gas recirculation systems. However, this article focuses solely on combustion engine valves and does not address check valves.

Engine valves are common to many types of combustion engines, regardless of the fuel type—gasoline, diesel, kerosene, natural gas (LNG), or propane (LP). These engines vary in design based on factors such as:

- The number of cylinders, which are combustion chambers where fuel ignition generates power.

- Operation type including 2-cycle (2-stroke) or 4-cycle (4-stroke) engines.

- Valve placement within the engine includes overhead valve (OHV), overhead cam (OHC), or valve in block (VIB) designs.

This article provides an overview of how engine valves operate in typical combustion engines and details the types of valves, their designs, and the materials used in their construction.

What is Engine Valves?

A valve is a device to close and opens a passage. Engine valves are devices that are used in internal combustion engines to allow or stop the flow of fluid or gas from cylinders or combustion chambers during the engine while the engine is operating.

These are also known as check valves, which are used for air injection in vehicles as part of emission control and exhaust gas recirculation systems.

Engine valves are commonly employed in every type of combustion engine, such as gasoline, diesel, kerosene, natural gas, or propane.

In motor vehicle engines, two engine valves are used for each cylinder inlet (or intake) valve and an exhaust valve. So, this article helps you to understand the different types of engine valves along with their functions and operation in combustion engines.

Function of Engine Valves

The cylinder head provides safety to the engine valves. The main function of the engine valve is to allow the fluid to flow into and out of the cylinder. The air helps to ignite the fuel. The produced power during the combustion of the air-fuel mixture is utilized to push the piston upward and downward.

The engine valve has the following two types:

Inlet Valve

The inlet valve is installed to transfer the fuel into the engine cylinder. It ensures the proper supply of fuel to the engine cylinder. As it is closed, the fuel flow into the cylinder stops.

The austenitic stainless steel is most commonly used for the construction of inlet valves. This material is a heat and corrosion-resistant material. Nickel-chromium alloy steel is also used for the construction of the inlet valve.

Exhaust Valve

The exhaust valve is also known as the discharge valve. It is used to discharge exhaust gases. Sili chrome steel is usually used for the construction of the exhaust valve. Sili chrome steel is an alloy of chromium and silicon.

The valves employed in the car engines are also known as mushroom or poppet valves. The valve head has a precision-ground surface with enough clearance to prevent a thin edge.

The angular surface is grounded at a 30° or 45° angle to the valve head to match the valve seat angle in the cylinder head. The spring retainer lock groove is located at the valve stem end.

Parts Of An Engine Valve

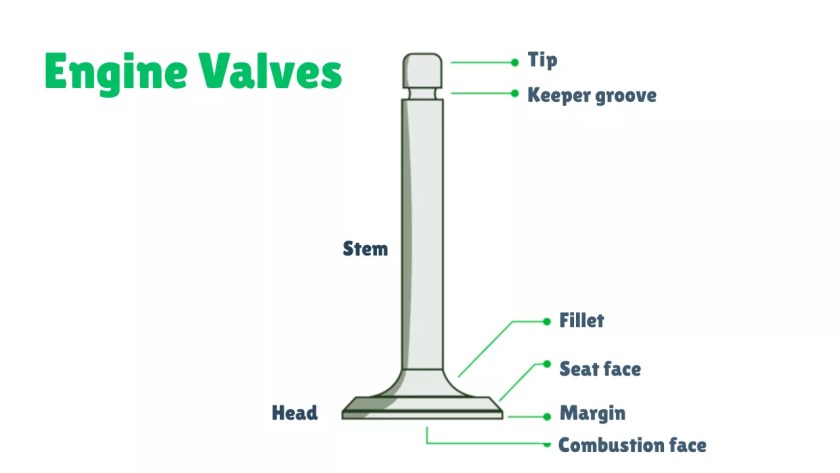

Most engine valves are designed as poppet-style valves, named for their characteristic up-and-down “popping” motion.

These valves feature a conical profile valve head that fits precisely against a machined valve seat, creating a seal to block or allow the flow of fluids or gases. Due to their distinctive shape, they are also called mushroom valves.

Figure 1: Various parts of an engine valve

An engine valve consists of two main elements:

- The valve head is the wide portion of the valve responsible for sealing against combustion pressure. The valve head includes a fillet that transitions into a seat face. The seat face is machined at a specific angle to match the valve seat, ensuring a tight seal against combustion pressure.

- The valve stem connects the valve to the mechanical components (e.g., rocker arms, camshafts) that control its movement. It transmits the force needed to lift the valve against the seating pressure exerted by the valve spring.

- The keeper groove, which secures the valve spring and ensures proper alignment, is located near the top of the valve stem.

- The valve tip is located at the tip of the valve stem and repeatedly makes contact with the rocker arm or camshaft, transferring force to open the valve against the spring pressure.

Types of Engine Valves

There are 3 different types of engine valves as follows:

- Poppet valve

- Sleeve valve

- Rotary valve

- Reed valve

#1. Poppet Valve.

It is the most commonly used valve in automobile engines. The name of this valve is given because of its popping up and down motion. This looks similar to mushrooms, hence it is also known as a mushroom valve.

A poppet valve consists mainly of two parts: one is the head, and the other is the stem. The face of the valve is inclined 30°-40° because it has to fit properly with the valve seat. The other part is the stem.

It is a long rod that has a spring retainer lock groove, and its one end is in contact with the cam, which is run by the crankshaft. The spring helps to seal the valve properly.

The intake valve is placed on the combustion chamber side, such that during the exhaust stroke, exhaust pressure helps to seal the inlet valve. The exhaust valve is placed on the manifold side such that the suction pressure helps to seal the exhaust valve during the suction stroke.

#2. Sleeve Valve.

A sleeve valve consists of a sliding tube-like structure between the piston and the cylinder valve. This sleeve has two-day ports in it for the inlet of fuel and the outlet of exhaust gases, and the same is the case with the cylinder.

The sleeve gets its vertical and rotational motion from the crankshaft of the engine.

When the inlet port of the sleeve and the inlet port of the cylinder coincide, the fuel enters the combustion chamber, and when the exhaust port of the sleeve and the exhaust port of the cylinder coincide, the exhaust gases vent out of the cylinder.

These types of valves have a simple construction and produce less noise.

Advantages

- These valves are simple in construction and are silent in operation.

- There is noise because there are no noise-making parts like valve cams, rocker arms, tappets, valves, etc.

- The sleeve valve has less tendency to detonate. Cooling is very effective as the valve is in contact with the water jackets.

#3. Rotary Valve.

A rotary valve has a motor-like structure. It has four values for the inlet and outlet, which are situated on the outer cylinder.

The inner shaft consists of a blade-like structure that is used to close and open the ports. The figure of a rotary value is given below.

Advantages

- Rotary valves are simple in construction and are manufactured at cheaper costs.

- They are suitable for high-speed engines.

- These valves have fewer stresses and vibrations.

- Rotary calves perform smooth, uniform, and noise-free operations.

#4. Reed Valve.

These are a type of check valve that opens and closes the flow of fluid in the same direction under varying pressure on each face. It consists of a mechanical bar hinged at one end that covers the passage and allows air or charge to flow in only one direction.

This valve is placed such that the suction pressure opens the inlet valve and closes the exhaust valve. And the exhaust pressure closes the inlet valve and opens the exhaust valve. These are usually installed in two-stroke engines.

Types of Engine Valve Mechanisms

The valves are operated by cams mounted on a camshaft. The camshaft gets motion from the crankshaft. As the camshaft turns, the cam operates the valve.

According to the location of the valves, the valve mechanism is of two types:

- Valve mechanism for operating the valve in the engine block (straight poppet valve).

- Valve mechanism for operating the valve in the cylinder head (overhead poppet valve).

Valve-Tappet Clearance

In the case of the overhead poppet valve, a slight clearance is kept between the valve stem and the rocker arm, while in cases of the straight poppet valve, a slight clearance is kept between the valve stem and the valve tappet. This slight clearance is known as the valve tappet clearance.

The valve tappet clearance permits the valve stem to expand as the engine warms up.

As the engine gets hot, the valve will not close properly without adequate clearance, resulting in loss of power and valve lifting. Therefore, it is best to have more clearance than the requirements, which may increase valvetrain noise slightly.

The valve-tappet clearance depends upon the following factors:

- Length of the valve stem

- The material of the valve.

- The temperature at which the engine operates.

Hydraulic Valve Lifter

It is very quiet in operation because it ensures zero valve tappet clearance. It automatically adjusts its length to compensate for differences in the valve. tappet clearance. Also, it usually requires no adjustment in normal service.

Its body consists of a cylinder and an oil reservoir. An opening in the body is connected with an oil pressure line from the engine lubricating system to supply the reservoir with oil.

A plunger fits inside the cylinder so that its upper end contacts the bottom of the pushrod, and its lower end is supported by oil between it and the bottom of the cylinder.

When the valve is closed, as at (a) (cam on the lower side), oil from the reservoir opens the ball-check valve and raises the plunger by passing between it and the cylinder bottom.

This produces zero clearance between the lifter unit and push rod, and between the rocker arm and valve stem.

When the cam turns to lift the lifter as at (b) (cam on the upside). The ball-check valve closes to prevent the return of oil to the reservoir and causes the entire lifter unit to lift the pushrod to open the valve.

Because the lift starts with zero clearance, the noise is reduced to a minimum. As shown in (b) during the lifting operation, a certain amount of oil is allowed to leak between the plunger and the cylinder.

This causes the lowering of the plunger to produce clearance if the spring does not raise it again when the pressure on the plunger is relieved by the closing of the engine valve.

This reopens the ball check valve, and oil again comes beneath the plunger, and the lifter is again set for zero clearance.

Eccentric Rocker Arm

The eccentric rocker arm automatically compensates for the difference in valve-tappet clearance. It consists of a conventional rocker arm modified to hold an eccentric by means of a slot and pin.

The plunger and spring control the piston of an eccentric. The plunger is activated by the spring and by oil pressure from an orifice in the rocker arm.

When the engine valve is closed (cam on the low side), the eccentric, under the action of the spring and plunger, moves to take up any clearance in the valve operating the train.

As the cam rotates to open the valve, the plunger and spring absorb any shock produced by this movement. When the cam is on the upside, the valve is completely open.

Valve Cooling

It is obvious that the exhaust valve runs hotter than the inlet valve because the exhaust valve is always in contact with the hot gases, while the inlet valve is somewhat cooled by the incoming fresh charge.

The exhaust valve may actually become red hot during a short period of operation. The valve face is the hottest, and the valve stem is the coolest part of a valve.

The valve stem passes heat to the valve guide, and the valve face passes heat to the valve seat, and this helps to keep the valve cool.

To provide adequate cooling, the cylinder head must be designed so as to permit good water circulation around the critical areas of the valve.

If the valve face fits properly on the valve seat and completely closes the combustion chamber, there will be no loss of compression and power.

In spite of this, the proper valve seating also provides full face contact with the valve seat through which more heat transfer can take place. Uneven contact may cause a valve to run several hundred degrees hotter than normal, which will shorten the valve’s life.

Sodium Cooled Valve

In many heavy-duty engines, sodium-cooled valves are used. A sodium-cooled valve has a hollow stem, which is partly filled with metallic sodium. Sodium melts at 97’5°C.

Thus, at operating temperatures, the sodium is liquid. When the engine is running, the valve moves up and down, and the sodium is thrown upward into the hotter part of the valve.

It absorbs heat, which is then given up to the cooler stem as it falls down in the stem again. This action keeps the valve head cool.

Sodium-cooled valve runs as much as 100°C cooler than a solid stem valve of similar design under the same operating conditions. This means a sodium-cooled valve has a longer life. But its use requires more care.

If the hollow stem of the sodium-cooled valve is cracked or broken, it is potentially dangerous. Sodium bursts into flame in contact with water. It causes a deep and serious burn on the skin. As long as sodium is safely in the valve stem, there is no danger.