As you guessed, machines like lathe, milling, and drilling are driven under manual control, and we are more dependent on people to perform and have a greater average of accuracy and precision in taking the time.

So to solve this dilemma, the machine developed CNC – Computer Numerically Controlled.

Computer Numerical Control (CNC) machines are extensively adopted in the industries of production. They are growing in leaps and bounds in these few years.

CNC machine is defined as a machining system that is under the control of a computer, they permit the manufacturer to automate many manufacturing processes that otherwise would have to be done manually.

As a result, CNC-powered machines are used to boost productivity, waste less, and even banish the prospect of human error. Using actuators, drives, and software programs, CNC machines create a lot of products.

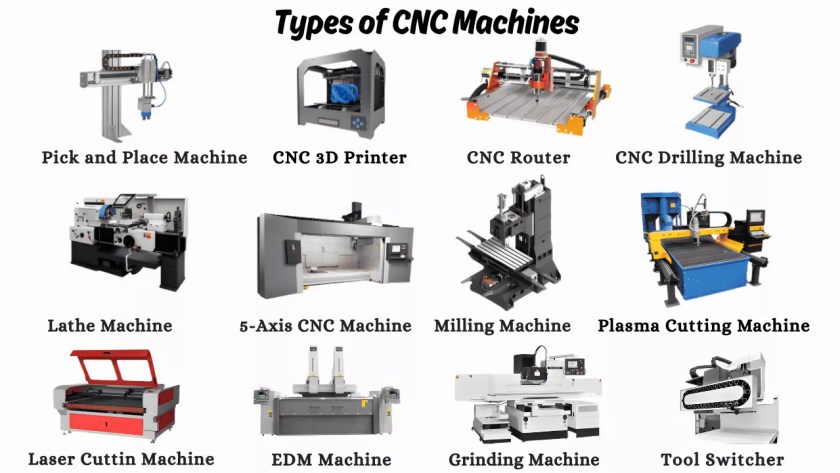

Types of CNC Machine

The following are the types of CNC machines:

- Lathe CNC machine

- Milling CNC machine

- Drilling CNC machine

- Grinding CNC machine

- Laser cutting CNC machine

- Plasma cutting CNC machine

- Electric discharge CNC machine

- Router CNC machine

- CNC machine with automatic tool changes

- 3-D printer

- 5-axis CNC machine

- Pick and place machine

#1. CNC Lathe Machine.

Lathe CNC machines have the capacity to turn in the machine. They have less number of axes than CNC milling machines, thus they are shorter and compact.

CNC lathe machines are made up of a lathe in the center, which manages and feeds the material programmatically to the computer. Therefore, it is widely used at the present time as a lathe due to its fast and accurate function.

Once programmed, a semi-skilled worker can operate it. This type of lathe is also used in mass production, such as in capstan and turret lathes. But there is no programmed feed system.

#2. CNC milling machine.

It is one of the most common types of CNC machines that uses built-in tools for drilling and cutting. In a milling CNC machine, materials are located inside it, after which the computer will lead the tools to drill or cut them.

Most of the CNC milling machines are available in 3 to 6 axes. This machine is also used to produce gears, such as a spur gear. The bore of the workpiece is drilled, and slots are made by inserting a part program into it.

Once programmed, a semi-skilled worker can operate it. It is also used in mass production on the same line as Capstan and turret. But there is no programmed feed system. Parts of this machine are very precise with respect to dimensional tolerance.

#3. CNC Drilling Machine.

This is a CNC drilling machine usually used for mass production. Drilling machines persisting also a multi-function machining center, are occasionally confused and sometimes twisted.

The longest sink time for CNC drilling is with tool changes, so the variation of hole diameter must be reduced for speed.

The fastest machine for drilling holes is several spindles in the turret with drills of different diameters pre-mounted for drilling. This type of CNC machine may also perform reaming, counterboring, and tapping holes.

#4. CNC Grinding Machine.

A precision performance tool that cuts metal away from the metal with a rotating wheel.

Typically, CNC grinding machines’ applications include camshafts, ball bearings, transmission shafts, and other working pieces that require an accurate and correct finish.

Most pieces made with a CNC grinding machine are cylindrical. Also, the grinding machine sometimes makes other types of workpieces. “CNC” here stands for computerized numerical control.

#5. CNC Laser Cutting Machine.

These machines are made to cut hard materials by using a laser to accomplish the task instead of a plasma torch. Although lasers are of high accuracy, they cannot match the plasma torch.

A laser-cutting CNC machine often uses CO2, neodymium (Nd), or yttrium-aluminum-garnet (Nd: YAG) lasers.

#6. CNC Plasma Cutting Machine.

The plasma-cutting CNC machines, similar to the milling CNC machines, are used to cut; unlike the milling machines, they perform the same operation using a plasma torch.

A plasma cutting machine is essentially a system that cuts by using an electrically conductive stream of an accelerated hot plasma. The machine features a high-powered torch that can cut through rough materials like metal or other hard materials.

#7. CNC Electrical Discharge Machine.

Also known as a spark CNC machine, this machine uses electric sparks to manipulate the materials into the desired shape. The electrical discharge has a transient effect, meaning that it is capable of degrading the elements from which it is projected.

The electric discharge CNC machines take advantage by generating sparks in a controlled manner to reshape the materials.

The materials are positioned between the top and bottom of the electrode, and then computers determine the amount of electrical discharge that the electrodes would produce.

#8. CNC Router Machine.

CNC router machine works similarly to the CNC machines such as lathe or milling. The primary difference is that everything a carpenter works on, like interior carving, door carving, exterior decoration, wood panels, signboards, wood frames, molding, musical instruments, furniture, etc., is all manually done.

According to the sketch, you design, if possible, create it in the system, then make it on the CNC router machine. The surface finish is better. It would be a very good machine, all in terms of door design and more.

#9. CNC Machine with Automatic Tool Changes.

Automatic tool changer CNC machine is applied to develop the tool carrying capacity and production rate of the machine.

And also used to improve the machine’s capacity to work with a number of tools. Tool changers on CNC Machine changes the tool very fast and easily, and changes worn out or broken tools.

The most important thing about this CNC machine is that it avoids nonproductive time. An automatic tool changer CNC machine is a perfect step toward complete Automation.

#10. 3-D Printer.

It is a CNC machine in which elements are printed layer by layer, design and drawing obtained by the CAD and CAM process, then the 3D printer is utilized to reflect that design, the 3D printer CNC machine is used for the printing of buildings and premises.

#11. 5-Axis CNC Machine.

5-Axis CNC machine is a machine with a total of Axes, which is actually 3 originally (X, Y, and Z). Any operation of any tool is done in 3 directions, but 2 more than (A, B) were added, deducted with 5 has the 5 Axes. A sculpture of this machine has produced.

#12. Pick and Place Machine.

Another type of CNC machine it is, utilized in the industry, pick and place CNC machine, with many nozzles that lift electrical components of electronic equipment, and these are placed in the correct location. Cellphones, computers, tablets, etc., are they used?

Conclusion

CNC machine is controlled using computers and makes the process more efficient, minimizes waste, and reduces human errors.

We hope you liked our article on “Different types of CNC machines with working”. If you have any queries, then do share them with us in the comments.